Client:

Manufacturing Plant

Requirement:

The client, a manufacturing plant, required a control system to optimize the operation of their oil pump and crusher motors. The oil pump motor was crucial for providing adequate lubrication to the crusher motor, both before and after its operation. The crusher motor, in turn, required precise control, contingent on the status of the oil pump motor to ensure efficient and reliable performance.

TekMinds Solution:

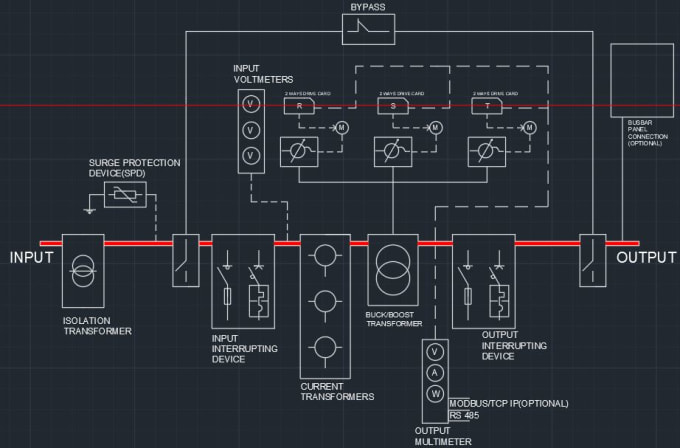

Our engineering team designed a control system that incorporated the following features:

- Timer Relays: Implemented On-Delay and Off-Delay timer relays to ensure the oil pump motor has a 3- minute pre-lube time before the crusher motor engages and a 6-minute post-lube time after the crusher motor disengages, providing adequate lubrication.

- Control Logic: Developed a control logic to coordinate the start/stop sequences of the motors, optimizing their operation and preventing premature wear.

By carefully synchronizing the operation of the oil pump and crusher motors, we ensured optimal lubrication and

efficient energy consumption.

Impact:

By implementing our solution, the client achieved:

- Improved Equipment Reliability: Reduced downtime and increased equipment lifespan.

- Enhanced Operational Efficiency: Optimized the production process and maximized output.

- Increased Safety: Mitigated the risk of accidents and equipment damage.

- Cost Savings: Lowered maintenance costs and improved overall productivity.

Through our expertise and innovative approach, we provided the client with a reliable and efficient control system

that met their specific needs